Till the end of 2017, length of crude oil and gas pipeline in China amounts to 133,100km, among which there is 77200km natural gas pipeline, crude oil pipeline is 28700km, refined oil pipeline is 27200km. These pipeline were constructed mainly by SMAW and semi-automatic welding. Since 2017, with the continuous expansion of the construction scale of cross country oil and gas pipeline and the continuous improvement of the requirements for pipeline welding quality, automatic pipeline welding has been fully applied in the projects.

At present, Russia to China natural gas pipeline is under construction. It is the first cross country pipeline project where automatic pipeline welding has been applied in China.

The first welding procedure of cross country pipeline welding is root pass welding. Only after the root pass welding is completed, hot pass, fill and cap welding can be carried out. Root pass welding restricts the overall construction speed of the project, so the time of root pass welding can be used to roughly measure the efficiency of automatic welding.

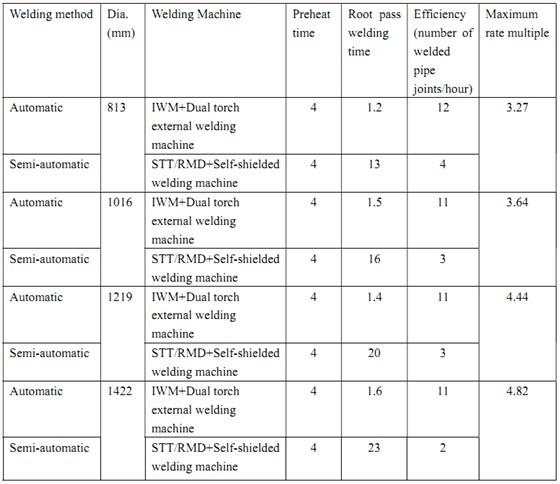

The following table is a comparison of the time and efficiency required for root pass welding with different pipe diameters and different welding methods:

It can be seen from the above table that compared with semi-automatic welding, automatic welding of cross country pipeline in line production can significantly improve the construction efficiency. At the same time, automatic welding of cross country pipeline also has the advantages of good welding quality, good quality consistency of welded joints, favorable for long-term safe operation of pipeline, low labor intensity of welders, etc. It is the direction of future development.

MPS Series Multi-process IGBT Inverter Welders

MPS Series Multi-process IGBT Inverter Welders Self-shielded Cored Wire Torch

Self-shielded Cored Wire Torch DI series ultra-high definition deformation detector

DI series ultra-high definition deformation detector XG Series Wire Feeders

XG Series Wire Feeders