Xionggu developed three types of automatic pipeline welding machine including internal welding machine, single torch type external welding machine, dual torch type external welding machine. Two welding processes have been developed: 1. Root pass by internal welding machine with solid wire+hot pass and fill & capping by dual torch type external welding machine with solid wire. 2. Internal line up clamp+root pass, hot pass, fill & capping by single torch type external welding machine with solid wire.

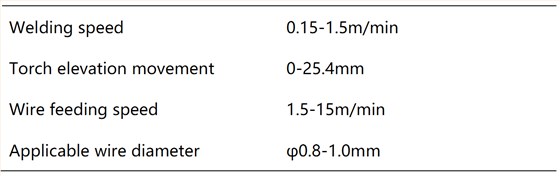

Welding parameters of internal welding machine

Welding speed 0.25-0.3m/min, wire feeding speed 9.0-10.0m/min. In case of 60° internal bevel, it is necessary to apply faster wire feeding speed. Therefore, welding speed is designed at 0.15-1.5m/min, wire feeding speed is designed at 1.5-15m/min.

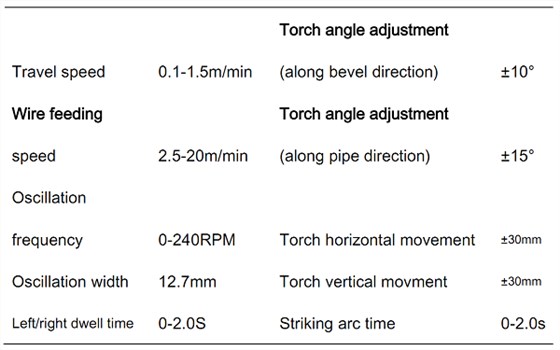

Welding parameters of single torch type external welding machine

Welding parameters of single torch external welding machine includes wire feeding speed, travel speed, oscillation width, oscillation frequency, left/right dwell time, torch vertical adjustment, torch horizontal adjustment.

Welding parameters of single torch type external welding machine

Welding parameters of single torch type external welding machine

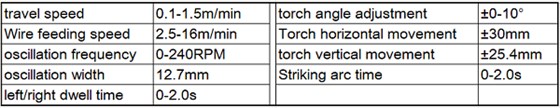

Welding parameters of dual torch type external welding machine includes wire feeding speed, travel speed, oscillation width, oscillation frequency, left/right dwell time, torch vertical adjustment, torch horizontal adjustment.

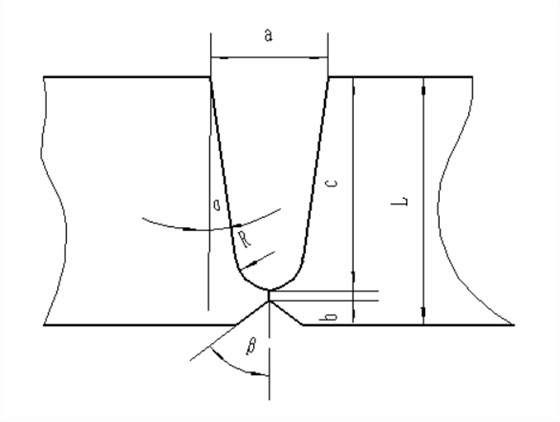

Bevel design

Dual torch external welding machine is designed for downhill welding. When solid wire is used, wire feeding speed is 7.6m/min-15.2m/min, travel speed is 0.25m/min-1.4m/min. According to this set of welding parameters, travel speed of dual torch welding machine is set to be 0.1-1.5m/min, wire feeding speed is set to be 2.5-16.0m/min.

Welding parameter

MPS Series Multi-process IGBT Inverter Welders

MPS Series Multi-process IGBT Inverter Welders Self-shielded Cored Wire Torch

Self-shielded Cored Wire Torch DI series ultra-high definition deformation detector

DI series ultra-high definition deformation detector XG Series Wire Feeders

XG Series Wire Feeders