In the previous article, we mentioned that Xionggu Company has developed two different automatic welding processes for automatic pipeline welding machine. For different welding processes, we have done the research of bevel design. Today, we will continue to explain the welding process.

Referring to currently popular automatic welding process for cross country pipelines in the world, it can be divided into two main categories: downhill welding and uphill welding. GMAW welding with solid wire is mainly used for downhill welding, while FCAW-GS welding with flux cored wire is mainly used for uphill welding.

Based on currently popular welding process in the world, two types of welding machine configuration are mainly used: single torch external welding and internal welding machine + dual torch. external welding machine. Today, we will talk about the welding process of single torch external welding machine along with related welding power source and shielding gas.

Welding process of single torch type external pipeline welding machine:Bevel design refers to previous article

Welding power source: Xionggu DPS-500P

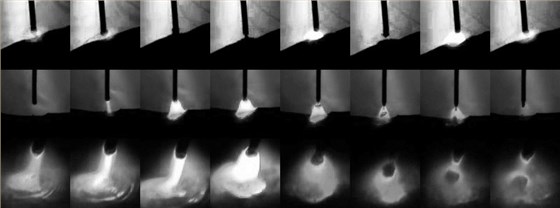

Root pass is done by Xionggu PST welding technology with precise short circuit transfer control to ensure root pass weld quality and forming. Fill and capping is the main factor of welding heat input in the whole welding process, which directly affects the mechanical properties of welded joints.

Moreover, for high grade steels, especially those above X80, the pulsed transfer can be used to control welding heat input and reduce the probability of weld crack. Therefore, the pulsed transfer mode is adopted for fill & capping with solid wire to do downhill welding.

Shielding gas: When the mixture of Argon and CO2 is used as shielding gas, it can reduce welding spatters and obtain enough penetration. For single torch external automatic pipeline welding machine, the mixture shielding gas is better.

MPS Series Multi-process IGBT Inverter Welders

MPS Series Multi-process IGBT Inverter Welders Self-shielded Cored Wire Torch

Self-shielded Cored Wire Torch DI series ultra-high definition deformation detector

DI series ultra-high definition deformation detector XG Series Wire Feeders

XG Series Wire Feeders