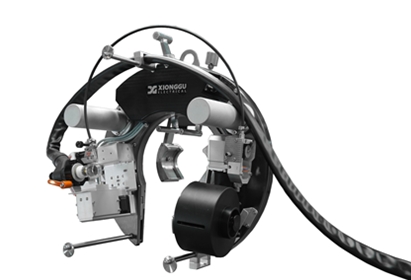

Home Single torch external welding machine

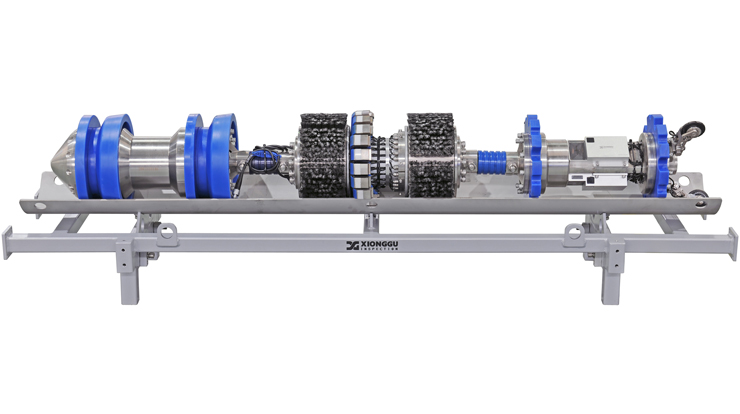

A-301 Series All position Pipeline Automatic Welding Machine

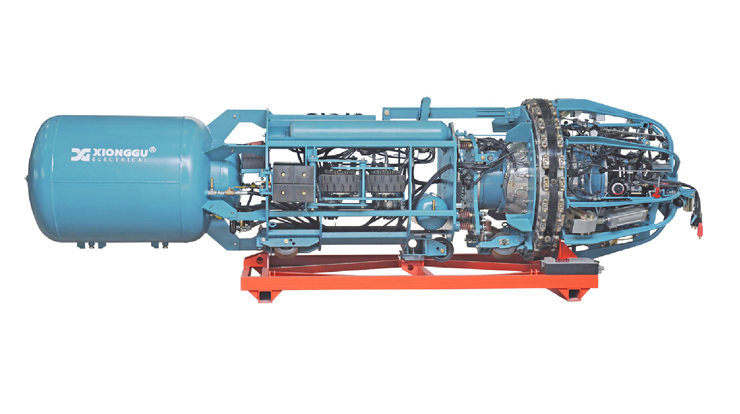

Product Introduction

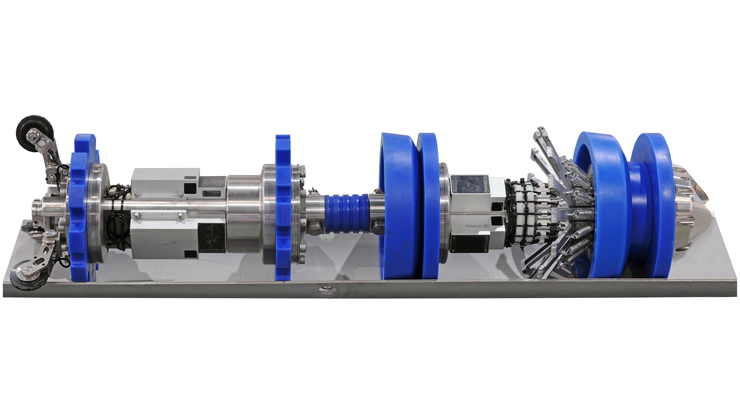

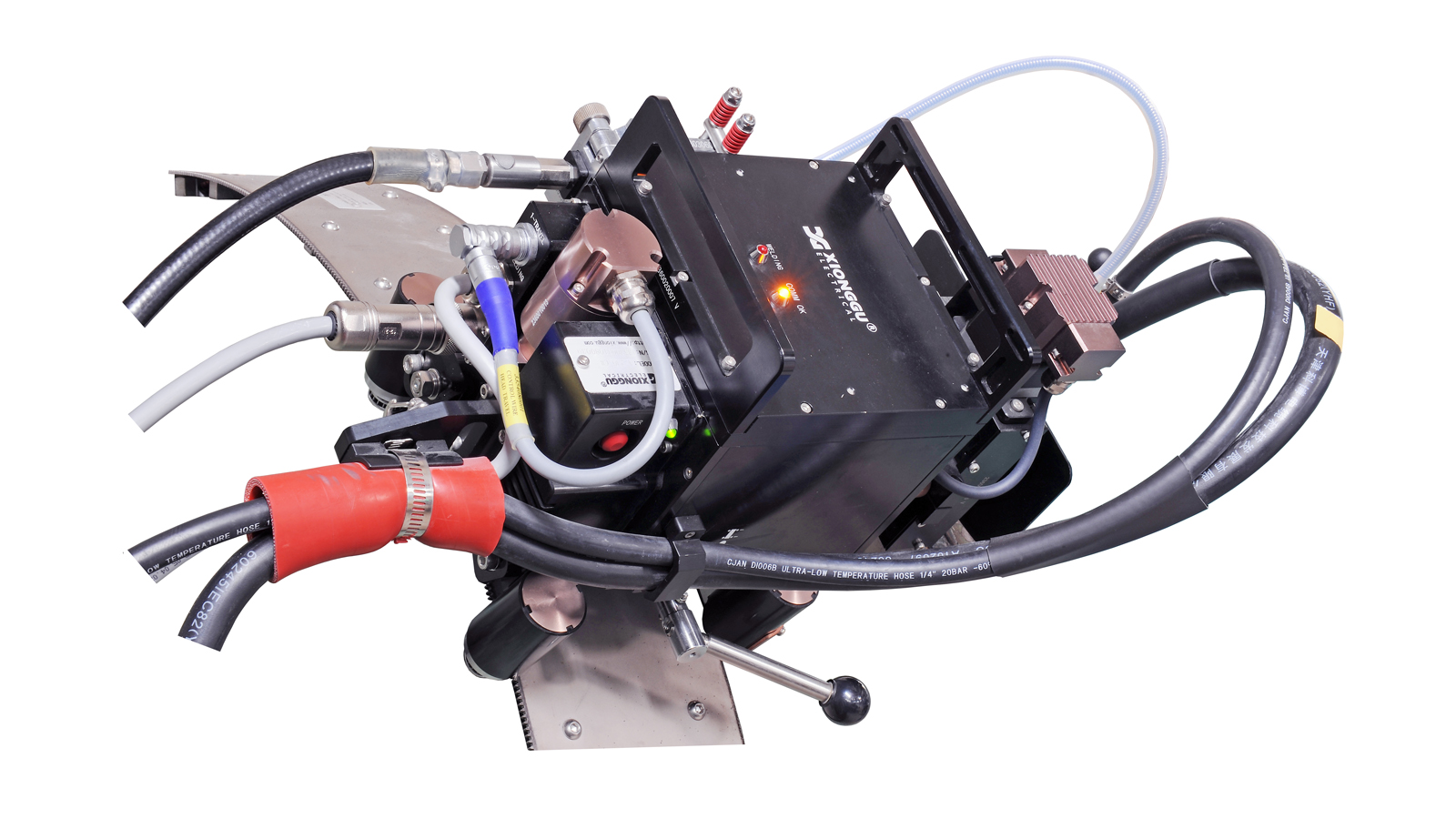

Function:Used for root pass, hot pass, filling and capping welding of pipelines in all positions, suitable for GMAW, FCAW, FCAW-G and GTAW welding processes.

Configuration:Welding head, industrial grade safety intelligent mobile terminal PDA , control cable,Digital welding power source

Product characteristics

- 01Industrial grade safety intelligent mobile terminal PDA (portable wireless LCD remote control) display and operation (with QR code scanning function), Chinese/English operation interface, convenient and intuitive.;

- 02By using arc sensor tracking and wire sensing positioning technology, as well as expert databases, we can reduce labor intensity and improve welding qualification rates;

- 03The replaceable TIG welding torch and gas shielded welding torch enable one machine to be used for multiple purposes, reducing user costs;

- 04Equipped with the newly upgraded DPS-500pro welding power source, rich in welding functions, and integrated development concept, the robot can seamlessly connects with the welding power source to meet customers' multiple welding needs;

- 05The travel speed and welding torch oscillation can be manually adjusted according to the welding seam status in a timely manner.

- 06The Linux embedded system platform has a built-in welding expert database;

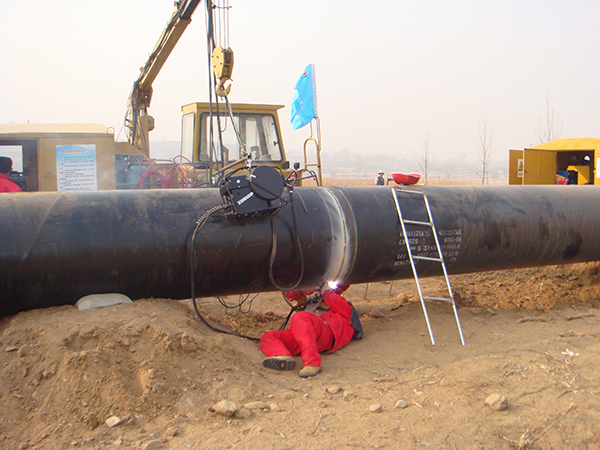

- 07It can achieve 360 degree circular welding;

- 08The welding head comes with a clamping function, no need for travel band, and is easy to use;

- 09Equipped with automatic arc tracking functions in vertical and horizontal directions, welders can learn quickly;

- 10Parameters can be set in section, the system automatically calls the corresponding parameters, reducing the difficulty and labor intensity of welding operations;

- 11Equipped with 4G, WIFI, and QR code scanning functions, it can provide remote technical services and data cloud transmission, facilitating real-time quality management;

Main Technical Parameters

| Model | A-301M/A-301MT | A-301L/A-301LT |

| Applicable pipe diameter | Φ53mm~Φ168mm | Φ159mm~Φ325mm |

|

Number of sections in every group |

1~360 Sections | 1~360 Sections |

| Wire feeding speed | 2.5~15 m/min | 2.5~15 m/min |

| Travelling speed | 0.1~1.5 m/min | 0.1~1.5 m/min |

| Weight of Wire Spool | 1.0 /5.0kg | 1.0 /5.0kg |

| Torch Oscillation Mode | Linear | Linear |

| Torch Oscillation Width | 0~20 mm | 0~20 mm |

| Torch Vertical Movement | 0~ 30 mm | 0~ 30 mm |

| Torch Horizontal Movement | 0~40 mm | 0~40 mm |

| Welding Seam Tracking | Arc tracking in vertical and horizontal axis | Arc tracking in vertical and horizontal axis |

| Ambient temperature | -40~55℃ | -40~55℃ |

| Altitude | 4500m | 4500m |

| IP Rating | IP54 | IP54 |

| Weight | 14.8kg | 17.8kg |

| Dimensions (W×L×H) | 410mm×350mm×470mm | 620mm×400mm×560mm |

Note: The parameters are for reference only, the actual product shall prevail.

System Composition

our cases

I want to place an order

-

Name*

-

Tel*

-

Email*

-

Msg*